31 Clove: Processing and Drying

31.1 Introduction

Cloves are the unopened flower buds of the evergreen tree Eugenia caryophyllus. The flowers develop in clusters of three to ten groups, each with three flowers per group. The young leaves are bright pink and change to a greenish yellow and harden. Cloves must be dried before they are stored and sold for market. The timing of harvest of the clove buds is critical. The buds should be harvested before the purple or crimson flowers start to develop. Clusters of flower buds are hand-picked from the branches. It is important that the branches are not removed or damaged as this will reduce the yield of future crops. The tree is native to the Moluccas (Spice Islands) a part of the Indonesian islands. Zanzibar and Pemba are now the world’s largest producers of cloves.

31.2 Processing of clove

The clove tree is a small evergreen tree that grows to a height of 12-20 meters. It thrives in coastal regions with temperatures between 15 and 30°C, average rainfall and a distinctive dry season (the optimum level of rainfall is 1750 to 2500mm a year). It is a low altitude plant that grows best at altitudes lower than 300m above sea level although it will also grow at altitudes above 900m.

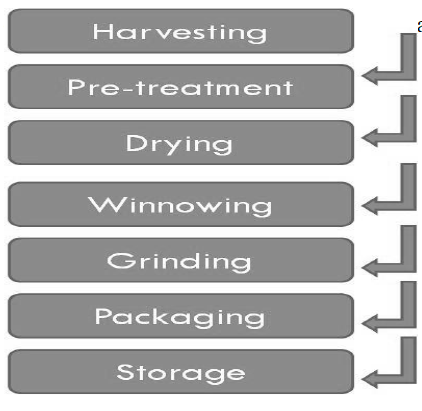

The young leaves of the clove tree are bright pink and change to a greenish yellow as they mature. Cloves are mainly used as flavoring agents in food industry, cigarettes (like kretek in Indonesia) and to produce essential oil used in dentistry etc. The correct time of harvest is when the outer green leaves (the calyx) of the flower bud change from olive green to yellow pink and before the petals fall to expose the stamens. The clove buds will first be cleaned and washed manually and then sun dried. Solar drying is the cheapest and popular mode of drying agricultural products. The dry clove bud enters to the milling unit in which milling and pulverization operations are carried out. The power is then sifted and tested according to standard procedures depending on the target market. It is then packed for sales. The detail art in figure 1.

Figure2. Flow chart for processing of cloves

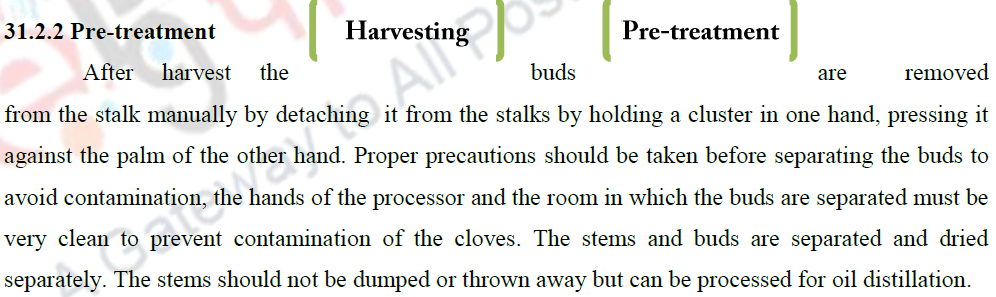

31.2.1 Harvesting

Time for harvesting is when the clove tree is of 6-8 years old, harvesting period is critical for clove bud. It should be harvested before the development of purple or crimson flowers. When the outer green leaves (the calyx) of the flower bud change from olive green to yellow pink, this is considered as best time for harvesting also this period is marked as prior to the petals fall. Clusters of flower buds are hand-picked from the branches. It is important that the branches are not removed or damaged as this will reduce the yield of future crops.

31.2.3 Drying

Buds should be processed or dried as soon as possible as they start to ferment. Sun drying is the common process used but other type of driers may be used. The cloves should be raked and turned frequently to ensure they develop an even brown colour. The colour of buds changes from pale russet to a darker brown as the clove dries. The drying process takes about four to five days. The final moisture content of the dried cloves should be 8-10%. Experienced clove driers will know when the cloves are fully dry as the buds will snap easily. During the rainy season, cloves should be dried using a mechanical drier such as a tray drier. The US Government and American Spice Trade Association standards for cloves are as follows:

- Moisture (% wet basis) <8%

- Extraneous matter <1%

- Mouldy buds <1%

31.2.4 Winnowing & Grinding

Winnowing is done to remove dust and other foreign matter. Small cleaning machines are available that use a blower to remove the dirt and dust. Other than that traditional processes like using basket for removing dust can also be considered for small scales. Grinding can be a method of adding value to a product. However, it is not advisable to grind spices. After grinding, spices are more vulnerable to spoilage. The flavor and aroma compounds are not stable and will quickly disappear from ground products. The storage life of ground spices is much less than for the whole spices. It is very difficult for the consumer to judge the quality of a ground spice. It is also very easy for unscrupulous processors to contaminate the ground spice by adding other material. Therefore most consumers, from wholesalers to individual customers, prefer to buy whole spices.

31.2.5 Packaging

Cloves can be packaged in polythene bags of various sizes according to the market demand. The bags should be sealed to prevent moisture entering. Sealing machines can be used to seal the bags. Attractive labels should be applied to the products. The label needs to contain all relevant product and legal information – the name of the product, brand name (if appropriate), details of the manufacturer (name and address), date of manufacture, expiry date, weight of the contents, added ingredients (if relevant) plus any other information that the country of origin and of import may require (a barcode, producer code and packer code are all extra information that is required in some countries to help trace the product back to its origin)

31.2.6 Storage

Dried cloves must be stored away from direct sunlight and must be stored in moisture-proof packaging materials. Also ensure that the cloves are fully dried before storage. Moisture will cause the cloves to rot and starts fermentation. The stored cloves should be inspected regularly for signs of spoilage or moisture. If they have absorbed moisture, they should be re-dried to a moisture content of 10%. The storage room should be clean, dry, cool and free from pests. Strong smelling foods, detergents and paints should not be stored in the same room as they will spoil the aroma and flavor of the cloves.

| you can view video on Cloves: Processing and Drying |