33 Grinding: Grinding Methods

33.1 Grinding: Grinding Methods

Spices play an important role in enhancing the flavor and taste of the processed foods. These spices are also used in the medicines because of their stimulating and digestive properties. These properties are enhanced by the process of grinding an age-old technique like grinding of other food materials.

The main aim of spice grinding is to obtain smaller particle size with good product quality in terms of flavoring and color. In thenormal grinding process, heat is generated when energy is used to fracture a particle into a smaller size. This generated heat usually is detrimental to the product and results in some loss of flavoring and quality. The fat in spices generally poses extra problems and is an important consideration in grinding. During grinding, the temperature of the product rises to a level in the range of 42±95°C which varies with the oil and moisture content of the spices, but spices lose a significant fraction of their volatile oil or flavoringcomponents due to this temperature rise. The losses of volatile oil fordifferent spices have been reported to be 37% for nutmeg, 14% for maceand 17% for cinnamon. The loss of volatile oil during grinding of caraway seed has been reported to be 32% with an increase in grinding temperature from 17°C to 45°C.

Spices are an integral part of Indian food, with consumption not only in households, restaurants and other eateries but also in food processing industry such as pickles, sauces, instant curry powders, ready-to-eat food preparations and so on. Hence, a spice grinding unit operation is recommended. After drying operation, grindingreduces the size of solid materials by mechanical action, dividing them into smaller particles by unit operation carried out by disintegrator and converted into powder by micropulvariser.

33.2 Size Reduction

Raw materials often occur in sizes that are too large to be used and, therefore, they must be reduced in size. Size reduction or ‘comminution’ is the unit operation in which the average size of solid pieces of food is reduced by the application of grinding, compression or impact forces. When applied to the reduction in size of globules of immiscible liquids (for example oil globules in water) size reduction is more frequently referred to as homogenization or emulsification. The size reduction of liquids to droplets is done by atomization. A similar range of particle sizes allows more complete mixing of ingredients (for example dried soup and cake mixes).

In the grinding process, materials are reduced in size by fracturing them. The mechanism of fracture is not fully understood, but in the process, the material is stressed by the action of mechanical moving parts in the grinding machine and initially the stress is absorbed internally by the material as

strain energy. When the local strain energy exceeds a critical level, which is a function of the material, fracture occurs along lines of weakness and the stored energy is released. Some of the energy is taken up in the creation of new surface, but the greater part of it is dissipated as heat. Time also plays a part in the fracturing process and it appears that material will fracture at lower stress concentrations if these can be maintained for longer periods. Grinding is, therefore, achieved by mechanical stress followed by rupture and the energy required depends upon the hardness of the material and also upon the tendency of the material to crack – its friability.

Grinders reduce crushed feed to powder. The product from an intermediate grinder might pass a 40 mesh screen; most of the product from a fine grinder would pass a 200 mesh screen with a 74 μm opening. An ultra fine grinder accepts feed particles no larger than 6 mm; the product size is typically 1 to 50 μm. Cutters give particles of definite size and shape, 2 to 10 mm in length. These machines do their work in distinctly different ways. Compression is the characteristic action of crushers. Grinders employ impact and attrition, sometimes combined with compression; ultrafine grinders operate principally by attrition.

Methods of grinding spices evolve over the years. Long time ago, when human beings started processing their food, they discovered that some plants can be stored longer and also tasted nicer if they were pounded with stones or grinded finely by batugiling. As for spices, for easy of transport, or as the recipe calls it, they are normally grounded. Methods for grinding spices for modern households normally include electric pepper grinder (for dry spices – like black pepper and cinnamon) or electric blender (for wet spices – like onion, ginger and chili paste).

In the old days methods of grinding spices are different. Before electric blenders, the spices were grounded manually. Every house had their own pestle and mortar made of undressed granite. This was used for grinding small quantities of spices for home-scale usage

33.1.1 Grinders

The term grinder refers to a variety of size reduction machines for intermediate duty. Product from a crusher is often fed to a grinder for further reduction. The grinding operation primarily consists of grinding mill and Pulvariser. Some of the commercial grinders are hammer mills, impactors, rolling compression machines, attrition mills, ball mill and tumbling mills.

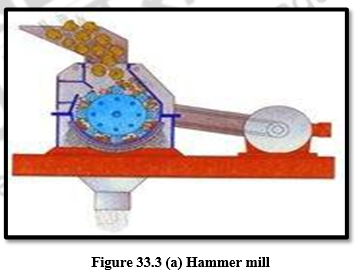

32.2.2 Hammer mills:

These mills all contain a high-speed rotor turning inside a cylindrical casing. Usually the shaft is horizontal. Feed dropped into the top of the casing is broken and falls out through a bottom opening. In a hammer mill, the particles are broken by sets of swing hammers pinned to a rotor disk.

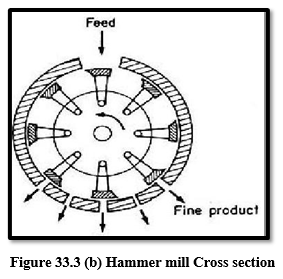

33.2.3 Micro-Pulvariser

Pulveriser is a high-speed hammer and screen mill, which accomplishes size reduction by mechanically impacting process material. This method of size reduction is characterized by relative high energy and short residence time, minimizing heat buildup during the millingprocess.

33.2.4 Operating Principle

The feeding material to be crushed enters the mill through a gravity feed hopper having an adjustable slide to control the feed material. The material is crushed between the hammers/blades and serreted liners.

The ground materials is continuously sucked by a powerful blower through a screen classifier and conveyed through the pipe into a Cyclone Drum for bagging. The blower maintains constant air flow in the grinding chamber in order to obtain a product and continuously cleans the screen. Particle size of ground material can be varied over a large range by using sieves with the desired opening.

33.2.5 Mini Pulveriser

Mini Pulveriser comprises of a heavy duty Mild Steel/Stainless Steel body, which comprises of a feeding hopper, with a feed regulator slide. The pulveriser body is inlaid with a delivery trough attached at the bottom, with a delivery trough attached at the discharged end. The rotor & beater are mounted on shaft, running in ball bearing housing at a speed of 4500-6000 R.P.M. The whole unit is mounted on a strong steel channel stand.

Application

Mini Pulvariser is widely used for grinding of dry/wet spices, green chilly, fresh ginger, garlic, fresh fruits, and vegetables. These machines can also be used as a fruit finisher. The Mini Pulveriser can also be used for the following dry applications like agricultural chemicals, broken biscuits (hi-fat/low fat), custard powder coffee, charcoal, dhal, dyes & pigments, fillers, henna leaves, herbs, leaves and roots instant foods insecticides and pesticides, kaolin moulding powders, pharmaceuticals, plastics, poultry feed & marine feed, resins, sugar (biscuit grade/icing grade), tea etc.

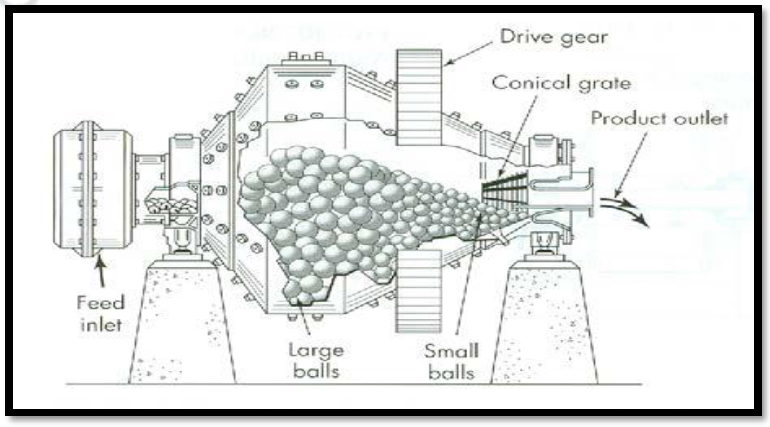

33.2.6 Ball Mill

A mill of this kind contains balls of different sizes, all of which wear and become smaller as the mill is operated. New large balls are added periodically. As the shell of such a mill rotates, the large balls move toward the point of maximum diameter, and the small balls migrate toward the discharge.

The initial breaking of the feed particles, therefore, is done by the largest ball dropping the greatest distance; small particles are ground by small balls dropping a much smaller distance. The amount of energy expended is suited to the difficulty of the breaking operation, increasing the efficiency of the mill. In a ball mill or pebble mill, most of the reduction is done by impact as the balls or pebbles drop from near the top of the shell.

When the mill is rotated, the balls are picked up by the mill wall and carried nearly to the top, where they break contact with the wall and fall to the bottom to be picked up again. Centrifugal force keeps the balls in contact with the wall and with one another during the upward movement. While in contact with the wall, the balls do some grinding by slipping and rolling over one another, but most of the grinding occurs at the zone of impact, where the free falling balls strike the bottom of the mill.

33.3 Cryogenic Grinders

Cryogenics is the study of very low temperature and its application on different materials including biological products. Cryogenics has numerous applications in space science, electronics, automobiles, the manufacturing industry, sports and musical instruments, biological science and agriculture, etc. Cryogenic freezing finds pivotal application in food, that is, spices and condiments. Although there is a wide range of cryogens to produce the desired low temperature, generally liquid nitrogen (LN₂) is used in food grinding. The application of low temperature shows a promising pathway to produce higher quality end product with higher flavor and volatile oil retention.

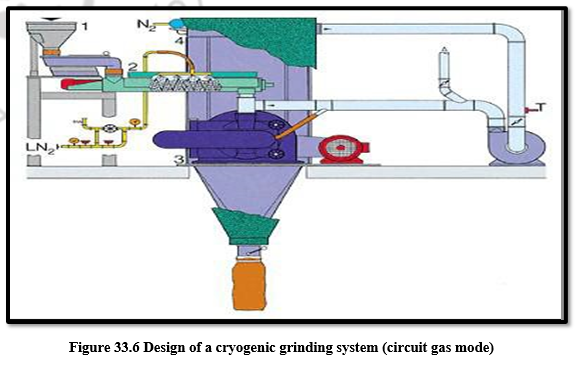

Cryogenic grinders generally consist of precooler and grinder with the cryogen distribution system. In such grinding systems, cryogens subject the raw material up to or lower than glass transition temperature before it is ground, thus eliminating much of the material and quality hassles of traditional grinding. At present, the capital investment including cryogen and handling costs escalate the final cost of the product. This is a new concept in spices processing, which results into higher production with better end product quality (aroma and color), than conventional spices grinding unit.

33.3.1 Process Description

The feed (At point 1) is introduced and liquid nitrogen (At point 2) at temperature of 195.6°C is sprayed on to the product which was later conveyed to hammer (At point 3) through a Screw conveyor. The product is disintegrated, screened and filled into bags by gravity method. The liquid N2 used is recollected (At point 4) through a refrigeration system for the process economy of the process

33.3.1.1 Mechanism of action

The fat content of spices poses problems of temperature rise and sieve clogging during grinding. Due to this temperature rise, spices lose a significant fraction of their volatile oil or favoring components. Therefore, a cryogenic grinding system was designed and developed to cool the spices before feeding to the grinder and also maintain the cryogenic temperature in the grinding zone. The main components of the cryogenic grinding system are a precooler and grinder as discussed. The precooler consists of a screw conveyor assembly, a compressor, a liquid nitrogen and power transmission unit. The increase in grinding temperature from160°C to 170°C resulted in a significant increase in particle size of the product and specific energy consumption in grinding. The loss of volatile oil can be significant reduced by a cryogenic grinding technique.

Liquid nitrogen at -195.6°C provides the refrigeration needed to precool the spices and maintain the desired low temperature by absorbing the heat generated during the grinding operation. In addition to maintaining the low temperature, vaporization of the liquid nitrogen to the gaseous state, in effect creates an inert and dry atmosphere for additional protection of spice quality. Precooling of the raw spice and the continuous low temperature maintained within the mill reduces the loss of volatile oils and moisture thereby retaining most of the flavor strength per unit mass of spice.

Many commercial powders must contain particles averaging 1 to 20 μm in size, with substantially all particles passing a standard 325-mesh screen that has openings 44 μm wide. Mills that reduce solids to such fine particles are called ultra-fine grinders. Ultra fine wet grinding is done in agitated mills.

| you can view video on Grinding: Grinding methods |