28 Turmeric: Grading & Curing

28.1 Introduction:

Turmeric is dried rhizome of herbaceous plant and is closely related to ginger. The spice is also sometimes called “Indian saffron” due to its colour. It is native to tropical South Asia and needs temperatures between 20°C and 30°C. The underground rhizome imparts a distinctive flavor to food but it is also used to provide food with a deep, indelible orange color. In the form of this fine, dried, yellow powder, turmeric is mostly sold to customers in developed countries. Turmeric is used in a wide variety of foods of the cuisines of Southern Asia but locally it also applies as an antiseptic for skin abrasions and cuts. India and Pakistan are significant producers of turmeric, which has regional names based on language and country. The name appears to derive from the Latin, Terra merita (merited earth), possibly related to saffron. Phytochememicals of turmeric has potential effect on cancer and the area of research for medicinal is widely exploring and is of main interest in India and abroad. Turmeric is considered highly auspicious in India and has been used extensively in various Indian ceremonies for millennia. Even today it is used in every part of India during wedding ceremonies and religious ceremonies.

It occurs in two tautomeric forms, keto and enol. The “keto” form is preferably a solid state and the “enol” form in solution. Curcumin can also be used as pH indicator, due to its property to change color at different pH, in acidic solutions it turns yellow, whereas in basic solutions it turns bright red. Turmeric contains up to 5% essential oils and up to 5% curcumin, a polyphenol. Curcumin is the active substance of turmeric. The Bengal type is preferred for use in dyes in India. It is interesting to note that in the United States, turmeric is considered as a spice by the food industry, whereas it is classified as a food colorant by the FDA.

28.2 Product of Turmeric

There are two dominant types of turmeric found: ‘Madras‘ and ‘Alleppey‘. These are also known as Primary products. The orange-yellow flesh Alleppey turmeric is predominantly imported by the United States, where users prefer it as a spice and a food colorant. Alleppey turmeric contains about 3.5% to 5.5% volatile oils, and 4.0% to 7.0% curcumin. In contrast, the Madras type contains only 2% of volatile oils and 2% of curcumin. The Madras turmeric is preferred by the British and Middle Eastern markets for its more intense, brighter and lighter yellow color, better suited for the mustard paste and curry powder or paste used in oriental dishes.

28.2.1 Dried rhizome

Turmeric is mostly imported as a whole rhizome, which is then processed into powder or oleoresin by flavor houses and the industrial sector. Rhizomes come as fingers, bulbs and splits. Fingers are the secondary branches from the mother rhizome, the bulb, and splits are the bulbs cut into halves or quarters before curing. The fingers are 2 to 8 cm long and 1 to 2 cm wide, and are easier to grind than the more fibrous bulbs and splits, and therefore command a higher price. Rhizome quality is judged by a clean and smooth skin, uniform skin and flesh colors, and a clean snap (or “metallic twang” as described by the Indian Ministry of Agriculture standards, Agmark) when broken. Turmeric cleanliness specifications for import pertain to whole rhizomes.

28.2.2 Turmeric powder

Ground turmeric is mostly used on the retail market, and by the food processors. Rhizomes are ground to approximately 60-80 mesh particle size. Since curcuminoids, the color constituents of turmeric, deteriorate with light and to a lesser extent, under heat and oxidative conditions, it is important that ground turmeric be packed in a UV protective packaging and appropriately stored. Turmeric powder is a major ingredient in curry powders and pastes. In the food industry, it is mostly used to color and flavor mustard. It is also used in chicken bouillon and soups, sauces, gravies, and dry seasonings. Recently the powder has also been used as a colorant in cereals.

28.2.3 Curry powder

Turmeric is such an important ingredient in curry powder that it merits special mention. In its export statistics of spices, the Indian Spice Board specifically lists curry powder exports. The turmeric content in curry powder blends ranges from 10-15% to 30%. Typical Indian curry powder for meat and fish dishes contains 20-30% turmeric, 22-26% coriander, 12% and 10% cardamom and cumin, respectively, 4% or 10% fenugreek, ginger, cayenne, cloves and fennel in proportions from 1% to 7%.26 Curry mixes for vegetarian dishes contain less turmeric, in the range of 5 to 10%, because of the bitter flavor it would impart to the dish.

28.2.4 Oleoresin

Turmeric extracts are obtained by solvent extraction of the powdered or comminutated rhizome. The compounds of interest in turmeric oleoresin are the curcuminoids (40 to 55%), and the volatile oils (15 to 20%). The curcuminoids, which consist mostly of curcumin (1,7-bis(4-hydroxy-3- methoxyphenyl)-1,6-heptadiene-3,5-dione), and also de-methoxy curcumin, and bis-demetoxy curcumin, can be further purified to a crystalline material, and will be used preferably in products where the turmeric flavor is undesirable, such as cheese, ice cream, beverages and baked products. Curcumin has similar color characteristics than the synthetic food colorant tartrazine. However, unlike tartrazine, it is highly sensitive to light and alkaline pH, and is also degraded by heat and chemical oxidants. It is therefore not easy to use in food processes and products destined to long-term storage.

28.3 Processing of turmeric:

28.3.1 Harvesting

Turmeric is harvested when the plants are between 7 and 10 months of age and when the stems and leaves start to dry out and die back. The whole plant is removed from the ground, taking care not to cut or bruise the rhizomes.

28.3.2 Sweating

The leaves are removed from the plant and the roots carefully washed to remove soil. Any leaf scales and long roots are trimmed off. The side (lateral) branches (which are known as the fingers) of the rhizomes are removed from the main central bulb (known as the mother). The mothers and fingers are heaped separately, covered in leaves and left to sweat for one day. The „mothers‟ are the preferred material for planting the following year.

28.3.3 Curing

Turmeric rhizomes are cured before drying, which involves boiling the rhizomes until it becomes soft. Curing is done to gelatinize the starch for a more uniform drying. During this process, the coloring material is diffused uniformly through the rhizome. The Indian Institute of Spice Research, Calicut, Kerala, and the Agricultural Technology Information Center simply recommend boiling in water for 45 min to one hour, until froth appears at the surface and the typical turmeric aroma is released. They report the color deteriorates as a results of over-cooking, but that the rhizome becomes brittle when under-cooked. Optimum cooking is attained when the rhizome yields to finger pressure and can be perforated by a blunt piece of wood. Curing is more uniform when done with small batches at a time. It is recommended to use perforated containers that allow smaller batches of 50 to 75 kg. Curing should be done two or three days after harvest, and should not be delayed to avoid rhizome spoilage. The benefits of curing turmeric include the following:

- Reduction of drying time

- More even colour distribution throughout the rhizome

- A more attractive (not wrinkled) product that is easier to polish

- Sterilisation of the rhizomes before drying.

28.3.4 Drying

The rhizomes are sliced before drying to reduce the drying time and improve the quality of the final product (it is easier to achieve a lower final moisture content in small pieces of rhizome without spoiling the appearance of the product). The rhizomes are traditionally sliced by hand, but there are small machines available to carry out this process. There are several different types of mechanical drier that are suitable for drying turmeric. These include the tray drier, cross flow air tunnels, solar driers and cabinet driers. The optimum drying temperature is 60°C, temperatures higher than this result in a darker coloured product.

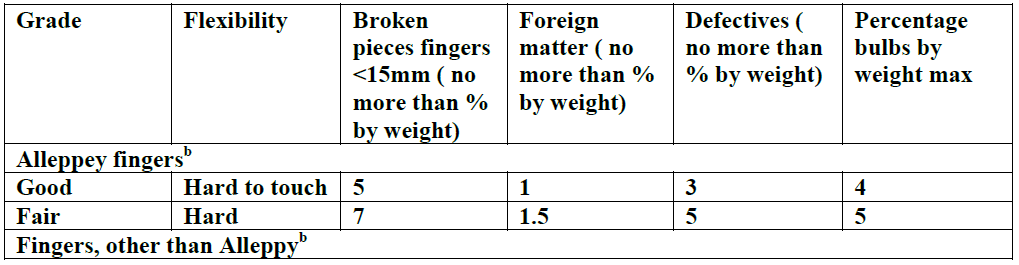

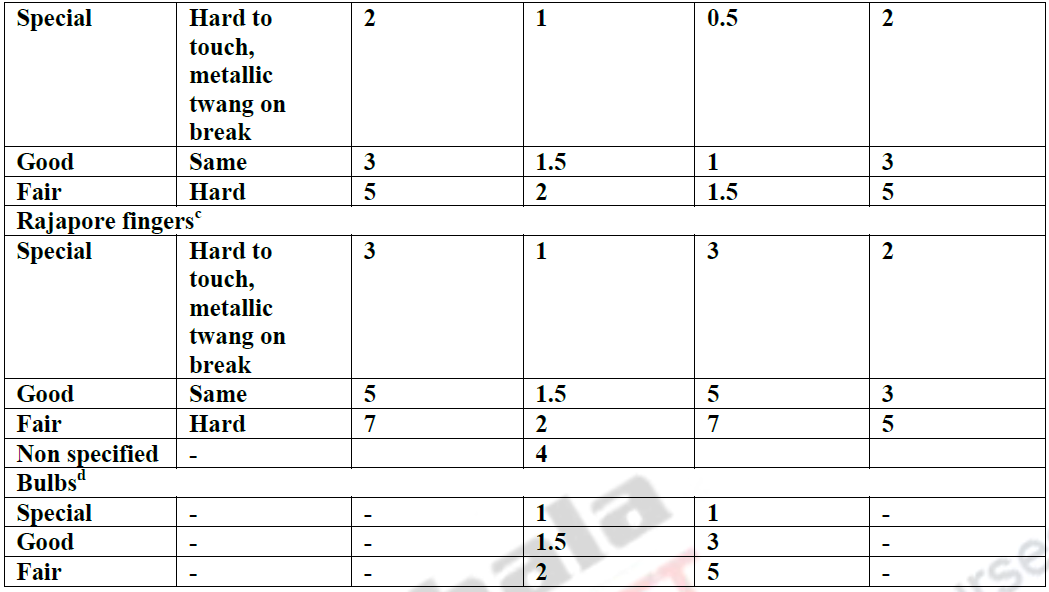

Table 1. Agmark standard for turmeric rhizomea.

a: http://www.turmeric.8m.com/standards.html

b: Fingers shall be of secondary rhizomes of Curcuma longa L.; shall be well set and close grained; free from bulbs; be perfectly dry and free from weevil damage and fungus attack; not be artificially coloured with chemicals.

c: same as (b); have the characteristics of the variety; admixture of varieties of turmeric allowed at a maximum of 2%, 5%, 10% and 10% in the four grades, respectively.

d: Bulbs shall be primary rhizomes of Curcuma longa L.; shall be well developed, smooth and free from rootlets; have the characteristics of variety; be perfectly dry and free from weevil damage and fungus attack; not be artificially coloured with chemicals.

28.3.1 Polishing

After drying the rhizomes are polished to remove the rough surface. This can be done by hand or by shaking the rhizomes in a gunny bag filled with stones. Polishing drums are used in many places

– these are very simple, power driven drums that have an abrasive metallic mesh lining. In some places the rhizomes are sprinkled with a solution of ground turmeric in water during the final polishing, to give the rhizomes a good color.

28.3.2 Grading

Quality specifications for turmeric are imposed by the importing country. They refer to the cleanliness of the product rather than on the eating quality. Bulk rhizomes are graded into fingers, bulbs and splits. The Indian standards for turmeric follow the Agmark Specifications (Agricultural

Directorate of Marketing) to ensure quality and purity of the products. The Agmark standards for quality of turmeric are as shown below in Table 1. Proper care must be taken to meet minimum requirements, otherwise a lot may be rejected and need further cleaning and/or disinfection with ethylene oxide or irradiation.

28.3.3 Grinding

Grinding of turmeric rhizome is cutting and crushing the rhizomes into small particles, then sifting through a series of several screens to get a fine powder. Turmeric is one of the few spices that is usually purchased in a ground form. The whole rhizome pieces may be exported and then ground in the country of destination. Alternatively, the dried rhizomes may be ground at the place of origin. Depending on the type of mill, and the speed of crushing, the spice may heat up and volatiles are lost. In the case of turmeric, heat and oxygen during the process may contribute to curcumin degradation. The flavour and aroma compounds are not stable and will quickly disappear from ground products. Cryogenic milling under liquid nitrogen prevents oxidation and volatile loss, but it is expensive and not widespread in the industry.

28.3.4 Packaging & Storage

Ground turmeric should be packaged in moisture proof, air-tight polyethylene packages. Turmeric pigment is highly unstable as compared to the yellow synthetic colorant, tartrazine. However, if protected from light and humidity; the curcuminoid pigments in turmeric powder and oleoresin are stable. Therefore, turmeric rhizomes and powder should be stored away from light and in a very dry environment.