20 Cardamom: Drying of fruits

20.1 Cardamom drying

The drying is the most critical process in the production of dried herbs and spices. The aim of drying is to reduce the moisture content of the product from actively growing in the field to a level that prevents deterioration of the product and allows storage in a stable condition. Drying is a two stage process: firstly the transfer of heat to the moist product to vaporize the water in the product and secondly mass transfer of moisture from the interior to the product surface where it evaporates. The most important and immediate management concern is to ensure the harvested crop will not rot or become grossly invaded with yeasts, bacteria and mould (producing aflatoxins) or become contaminated by pests. This is the start of the preservation process, which for most spice crops requires drying that will enable the long-term crop storage and the opportunity for further processing. The drying phase of post-harvest management can include four preliminary stages – the selection of high quality produce from the field; cleaning the crop by washing and disinfection; preparing the crop for drying by peeling or slicing; pre-treating with anti-oxidants, blanching or sulfurizing. In some cases, washing prior to processing is desirable to remove field contaminants (dust, soil) using anti- microbial solutions to reduce the microbial populations to a low level prior to the drying process.

Cardamom capsule colour and the retention of greenness are important for highest quality. Capsules cured immediately after picking retained greener colour and the loss of greenness was more significant if the capsules were stored for more than 12 hours. Bagging of the capsules in jute bags, and cool storage, aids the retention of greenness. Cardamom capsules at picking contain 70-80% moisture and to enable storage the moisture has to be. Sun-drying is generally undesirable for cardamom because of bleaching and capsule splitting. The most widely-adopted drying system is a slow dry over 18-30 hours using a number of methods of artificial drying (electric, kiln, bin) with various methods of hot air flow. A temperature between 40- 50°C helps retain the green colour and an increase in temperature significantly increases the percentage of yellow capsules, split capsules, and heat injury.

There are four main types of drying. The most basic method of drying is to spread the crop on a surface exposed to the sun. In this case, the process is aided by a cover system that prevents wetting with rainfall. An improved method, speeding up the drying, is to use a fuel source (wood, oil/diesel, gas or electricity) to heat the drying room. Solar drying systems together with solar powered fans are also available. The drying process should dry the crop as quickly as possible, at temperature levels which do not drive off the volatile flavour compounds. The drying temperature regime will be specific to each crop as will be the final moisture percentage for storage .The traditional open sun drying that is widely used in developing countries has major inherent limitations when trying to preserve product quality. High crop loss and low product quality result from inadequate drying, long drying times, fungal spoilage, insect infestations, bird and rodent damage and contamination plus the effects of sunlight and the weather. Even in the most favourable climate it is often not possible to get the moisture content of the product low enough for safe storage. In the tropics the high relative humidity of the air prevents drying of harvested crop products during the wet season.

The objective of a dryer is to supply the product with more heat than is available under ambient conditions. A relatively small amount of heating can greatly enhance the moisture carrying capability of the air. For example, heating air from 20°C at 59% relative humidity (RH) to a 35°C at 25% RH increases the moisture holding capability three times. In a dryer the major requirement is the transfer of heat to the moist product by convection and conduction. The absorption of the heat by the product supplies the energy necessary for the vaporization of water from the product. The process that occurs at the surface of the product is simply the evaporation of the moisture. The moisture replenishment to the surface is by diffusion from the interior and this process depends on the nature of the product. Spices and essential oil crops derived from leaves or flowers are relatively thin and therefore relatively easy to dry due to their small diffusion thickness. Conversely in thick and fleshy materials such as roots, the drying process requires much more careful control of temperature, temperature ramp rate and airflow rate. If the temperature is too high, elevated too quickly or the airflow rate is too high when drying thick fleshy products, ‘case hardening’ may result, and only the outer surface will dry. This dry layer becomes impervious to subsequent moisture transfer.

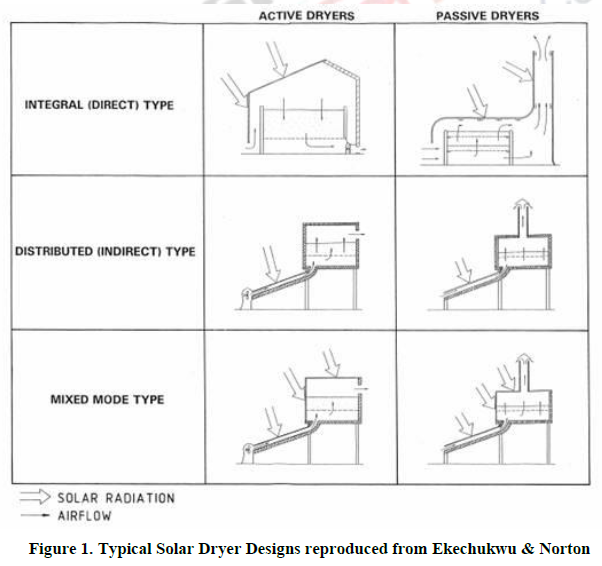

In many rural locations, grid electricity and supply of other non-renewable sources of energy are too expensive, unavailable or unreliable and drying systems that use mechanical fans and electric heating are inappropriate. The high capital- and running-costs of fossil fuel-powered dryers presents an economic barrier to use by small-scale farmers. Solar-energy drying systems are put forward as technology for small rural farmers and enterprises in developing countries. Solar dryers can be classified into two generic groups, passive or natural air circulation solar dyers and active or forced convection solar-energy dryers (Fig. 1).

Forced convective dryers employ motorised fans for circulation of the drying air. The electricity for the fan can come from a solar photoelectric panel and battery. Each group can also be sub-divided into three subgroups:

i) integral types (direct solar dryers where the crop is placed in a drying chamber with transparent walls, and the solar radiation falls directly on the crop, coupled with convection air flow from the heated surrounding air)

ii) distributed type (indirect heating, where solar radiation heats a solar collector external to the drying chamber),

iii) A mixed type where there is both direct and indirect heating.

The integral type dryers are simple in both construction and operation and require little maintenance. However, they are likely to operate at lower efficiency due to their simplicity and there is less control of the drying operation. The distributed type are much more elaborate structures so require greater investment in materials and running costs, but have higher efficiency and as a result product quality is generally higher. The solar dryer has two significant disadvantages: a limited ability to process crops when the weather is poor; and drying can only occur during the daytime. This not only limits production and extends the drying time but also may have an adverse effect on production and product quality particularly fleshy crop products such as roots and stems that typically have drying times of several days. This has led to the development of hybrid systems with auxiliary heating systems such as burners using biomass, biogas or fossil fuels. Alternatively, to achieve more efficient energy use, some active solar dryers are designed with thermal storage devices (mainly rocks or gravel) to extend the drying time during the night time and in periods of low sunshine. Desiccants (such as clay and rice husk) can be incorporated in the design to reduce the relative humidity of the drying air so as to improve the moisture carrying capacity. The use of desiccants is only possible in forced convection systems as they increase the resistance to airflow.

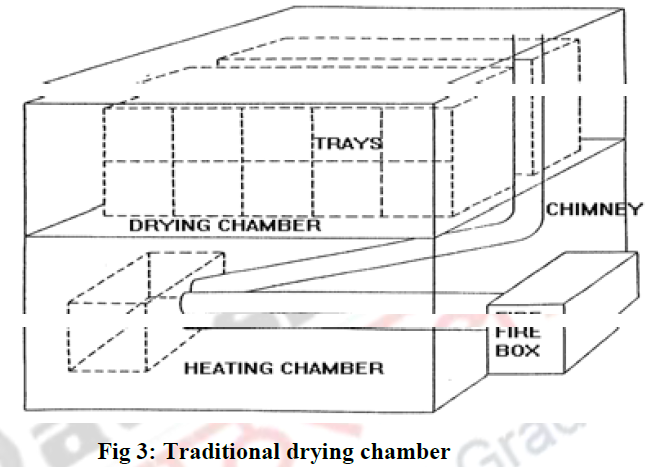

Cardamom curing may be defined as the process in which moisture of freshly harvested capsules is reduced from 80 percent to 10-12 per cent through indirect heating. Drying is the most important unit operation that determines the colour of the end products. Apart from quality in terms of colour, flavour component such as 1-8 cineole , terpenyl acetate, linalool etc are also important The traditional firewood based curing house consists of wood burning surface, flue pipes and drying racks in chamber. The furnace is made up of fine bricks or thick iron plates to facilitate charging with wood logs. Drying should be carefully controlled and should not be too rapid, temperature, humidity and aeration may be checked at frequent intervals during the course of drying.

The harvested capsules are spread in a single layer on trays. After keeping cardamom trays in the racks curing room is closed and heating is done by burning firewood in the furnace. The hot air passed through the pipes placed a few centimeters above the floor enhances the room temperature to 45 ñ 550C and this temperature status should be maintained for three to four hours initially. At this stage the capsules sweat and with the enhanced temperature, give off moisture. The ventilators are opened for sweeping out water vapour from the drying fruits. Exhaust fans can also be used for the speedy removal of moisture. After the complete removal of water vapour, ventilators are closed and the temperature inside the chamber should be maintained again at 45 -550C for about 18 to 24hours.

At frequent intervals (three-four hours) ventilator exhaust fan are to be opened to remove the excess moisture otherwise water vapour settles down on the capsules and it leads to cooking effect thereby looses the colour of the capsules. The temperature is again raised to 60 – 650C for another one or two hour for completing the curing process. The temperature is raised to hasten the cleaning process removing debris like stalks attached the capsules. Avoid raising temperature above 65o C inside the curing house to reduce splitting and loss of volatile oil. Black coloured blanket kept on the capsules spread under the sun will augment the drying process and also provides green colour to the cured produce.

Dried capsules have to be polished either manually or with the help of machines before marketing. Polishing is done by rubbing the dried capsule in hot state against the hard surface. Polishing machine is also available which can be operated either manually, or with electric motor. Motorized machines like Carpol can be used for polishing as well as grading of capsules having desired mesh. Agmark grades and

Indian specifications or standards are on the basis of important quality factors like colour, weight per volumeliter), size and percentage of empties, malformed, shrivelled and immature capsules. After grading, cardamom capsules can be stored over long duration. For efficient retention of green colour during storage, cardamom should be dried down to a moisture level of 10-12 per cent. Use to 300gauge black polythene lined gunny bags improves the storage efficiency. Store the commodity in wooden boxes at room temperature preferably kept in the curing house for better storage effectively.

20.3 Various methods of drying

There are several methods that can be used for drying of cardamom. Each method has different advantages and disadvantages.

20.3.1 Sun drying:

Traditionally, cardamom capsules are spread on a concrete floor to dry using the natural heat from the sun. The capsules should be placed away from direct sunlight to preserv the green colour (strong sunlight will make the colour fade). This is the simplest and cheapest method, but does not produce the highest quality product. It is only successful in places where the climate is dry and hot. During the monsoon season for example, drying will be interrupted by rainfall which can cause mould to grow on the capsules. During drying, the capsules may be contaminated by dirt and dust from their surroundings.

20.3.2 Solar drying:

The use of a solar dryer should improve the quality of the dried capsules as it is a cleaner, more controlled environment. However, it is not a popular choice as the green colour is lost during drying. The solar dryer is really only useful in dry hot sunny climates. The capsules should be placed in the dryer, out of direct sunlight, and dried until they have a final moisture content of 10%. In places with high humidity the solar dryer can only be used together with an extractor fan to remove the humid air.

20.3.3 Wood-fired dryer:

In India, cardamom capsules are traditionally dried in curing houses, using wood to provide the heat. This method puts a huge demand on firewood. The smoke from the fire can give the capsules an unpleasant smoked flavour. The processor must ensure that the capsules closest to the heat source are not burnt or scorched. Cardamom capsules dried by this method are not of the highest quality.

20.3.4 Electric or gas dryer:

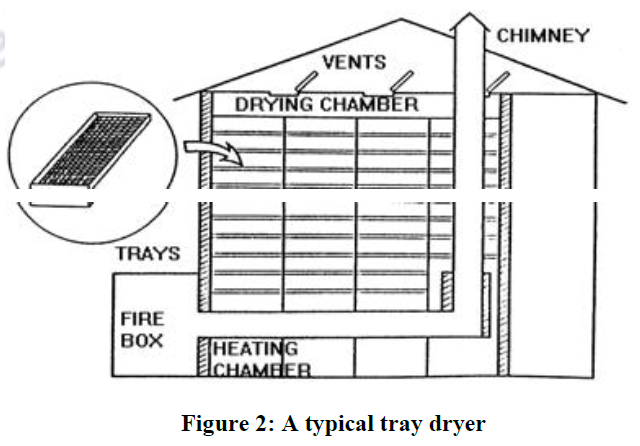

An electric or gas-fired dryer is an improvement over the use of a wood fuelled fire and is the best choice for drying large quantities of cardamom, especially in places where there is rainfall during the drying season. It is the most expensive of all options but does produce the highest quality product. It is important that the drying temperature does not exceed 50°C. A range of dryers of different sizes are available depending upon the individual choice and budget. Figure 2 shows a typical tray dryer.

20.3.5 Humidity-controlled drying:

A drying chamber has been developed that helps to reduce colour loss and to produce high quality pods. The cardamom capsules are placed in the drying chamber, which is at a temperature of 50°C. During the first two hours of drying, the humidity builds up within the chamber. This allows the cardamoms to ‘cook’ and at the same time destroys the enzymes that break down the chlorophyll (chlorophyll gives the pods their green colour). No light is allowed into the drying chamber. After two hours the humid air is blown out of the chamber and the humidity reduced. The capsules are left in the chamber to dry until they have a final moisture content of 10%. Figure 3 shows a traditional drying chamber.

20.3.6 The use of biomass gasifiers:

Electricity and liquefied petroleum gas (LPG) are clean and convenient fuels for drying, but are not cheap or easily available in villages. Firewood, stubble and dry leaves are readily available in villages, but they are smoky and can contaminate the dried product. A gasifier is a device that has been developed by TERI (The Tata Energy Research Institute in India) for use in the drying of cardamom. The gasifier uses briquettes that are made from firewood and other types of biomass and turns them into a gas that burns with a clean smokeless flame. The main advantage of using a gasifier is that it is more efficient in terms of the amount of fuel used. Biomass that burns in an open fire loses about two thirds of its energy as smoke. This system therefore uses less fuel and produces a higher quality dried cardamom. The gasifier for drying cardamom, developed by TERI, can be made locally using recycled oil drums.

20.4 Drying of large cardamom (Amomum spp.)

Fresh large-cardamom capsules contain about 70±80% moisture (on wet basis) depending upon the maturity level of the capsules at the time of harvest. The whole bunch of cardamom capsules is harvested from august to September, at the end of rainy season but before harvesting the paddy and later each capsule is separated from the bunch /fower and cleaned before drying. In order to achieve a long shelf life and to bring out the aroma, the moisture content has to be brought down below 10% (wet basis) and this process is known as curing, which has to be done immediately after harvesting to avoid fungus infection. In the traditional method, cardamom capsules are spread on a mesh and exposed directly to smoke. There is no control on fire and smoke, resulting in poor quality of the dried product. In order to overcome the drawbacks of traditional curing chambers, the Spices Board (a government agency under the Ministry of Commerce) tried to promote the flue-pipe curing chamber generally used in south India for curing of small cardamom. However, the flue-pipe method was found to be slow and also required a very large initial investment, without any energy savings, and has not crossed the demonstration stage as yet. As drying is done during rainy season, peasants consider it generally preferable to smoke the product.50 kg of seed capsules require 5-7 days for smoke drying. The ratio of fresh weight to dry weight is about 5:1, thus 5kg of fresh harvested capsules will yield 1kg of dry capsules.

20.5 Processing of large-cardamom in traditional bhatti

The fresh large-cardamom capsules contain about 70{80% moisture (on wet basis) depending upon the maturity level of the capsule at the time of plucking. Unlike the practice in southern India, where only matured capsules are plucked, the whole cardamom capsule bunch is plucked in Sikkim. Later on, each capsule is separated from the bunch/flower and cleaned for drying. In order to achieve longer storage life and also to bring out its aroma, it has to be dried to reduce the moisture content to a level below 10% (on wet basis). There are two methods by which cardamom is dried.

1. Traditional method (bhatti).

2. Improved flue pipe curing house.

20.5.1 Traditional bhatti system

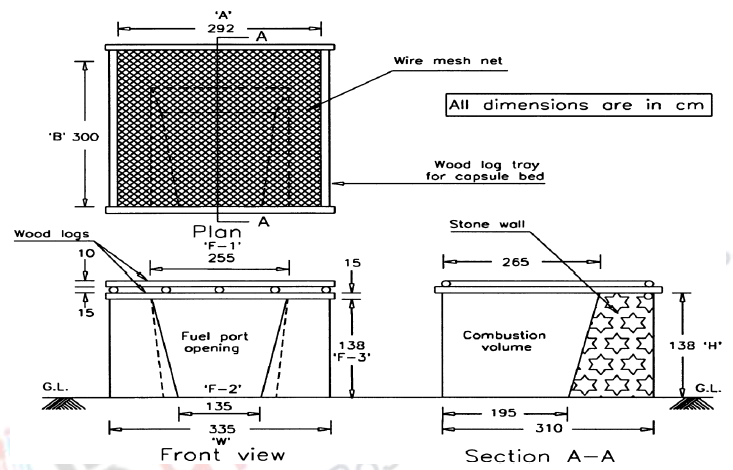

In the traditionally followed system of drying, the fresh cardamom capsules are dried in a locally made curing house commonly known as bhatti. A schematic diagram of the traditional bhatti is given in Fig below showing its structural details and configuration. It consists of a 0:6m thick stone wall structure on all four sides with an opening of about 0:75 m-1:00m in the front to make the _re. On the top of this stone-walled structure a meshed platform, made up of a locally available bamboo mat or chicken wire mesh is placed. It is supported on 0:100{0:150m diameter wood logs. On top of the mesh 0.150{0.200m diameter wood logs are placed on all four sides (cardamom bed area ranges from 4 to 9m2 depending upon the capacity of the bhatti) so that cardamom capsules can be spread within these border logs on the mesh structure. The mesh is placed about 1.2{1.8 m above the ground level where Fire is located. This height is probably necessitated in order (i) to reduce the charring and burning of cardamom capsules due to flying sparks and (ii) to keep the flue gas temperature below a certain level to prevent over drying. Capsules collected in the estate throughout the day are brought to the curing chamber or bhatti in gunny bags or bamboo baskets. Individual capsules are separated from the bunch, as while plucking the whole capsule bunch is cut from the plant. The fresh capsules are spread in a 200{250mm thick bed on the wire mesh tray by uniformly spreading it with a bamboo or spoon-like wooden spreader. After completion of spreading the fire is ignited.

After completing 20{24 h of drying the capsules are overturned. For this purpose, dried capsules are collected in the bags and partly dried capsules are spread on the meshed structure as bottom layer. Then on this layer the dried capsules are spread. This accelerates the drying process of capsules in the bottom layer and helps in maintaining uniformity in drying operation. After the reshuffling of capsule bed is completed the fire is again accelerated to complete the drying in the next couple of hours. In traditional bhattis the total cardamom drying time varies from 25 to 40 h depending upon several factors such as (i) initial moisture content of capsules, (ii) bhatti structure (opening, mesh, leakage holes, etc.), (iii) _re level maintained (operator tries to maintain low level of fire in bhattis having bamboo mesh and low height taking more time), and also on weather conditions.

20.5.2 Improved flue pipe curing house

About a decade back the Spices Board introduced improved curing houses on a trial basis. The design is similar to the conventional small cardamom curing chambers being used in Southern India. In this system, there are several wooden trays arranged in stacks. On these wire mesh trays fresh cardamom capsules are spread for drying. Firewood is burned in the furnace and hot flue gas obtained is passed through a network of flue pipes laid down inside the curing chamber. The unit operates on the principle of space heating. The room air surrounding the pipe gets heated up by natural convection and radiation. These systems are of two capacities | 200 and 800 kg. So far, the Spices Board had installed 20 units of 100 kg capacity, 152 units of 200 kg capacity and 1 community-type unit of 800 kg capacity improved cardamon curing houses in Sikkim.

| you can view video on Cardamom: Drying of fruits |