10 Pepper: processing of pepper

10. Pepper processing

Black pepper (Piper nigrum), the king of spices, is one of the oldest and the most popular spices in the world. It is a perennial, climbing vine indigenous to the Malabar Coast of India. The hot pungent spice made from its berries is one of the earliest spices known in India. Black pepper is grown under a variety of agricultural schemes ranging from home gardens, mixed crops in coffee plantations and monocrops on slopes and in valleys. After almost three years, the plants are over 2 m tall and are bushy. They start flowering at the onset of rains. The fruits are picked by hand, and are harvested 6 to 8 times each season at two-week intervals. A long rainy season, fairly high temperatures, and partial shade are required for the best growth of plant. Different varieties of pepper available are Betel pepper (Piper betel), Indian long pepper (Piper longum), Java long pepper (Piper retrofractum), Rough leaved pepper (Piper amalago), etc. Pepper plant is a native of the Malabar Coast in Kerala. At present India accounts for more than 20% of the world output of pepper and is also one of the largest consumers and exporters of pepper. Kerala is the largest producer of pepper accounting for over 95% of India’s total output. Pepper is cultivated in Kerala in Idukki, Kottayam, Cannanore, Calicut and Wayanad. Pepper is also cultivated in Karnataka, Tamil Nadu, A&N Islands and Pondicherry.

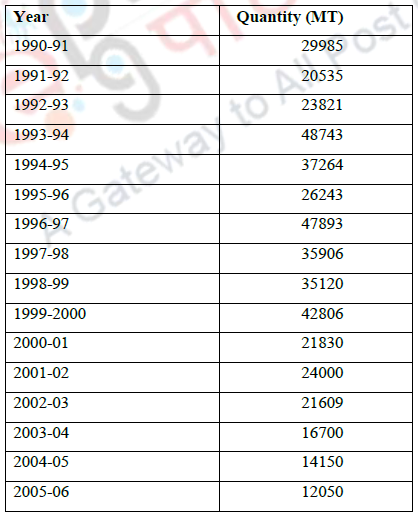

Pepper export data of India

Post-harvest handling is crucial to get a high-quality product. The harvested spikes are kept in bags for 12–24 hours or heaped and covered overnight for a brief fermentation which makes despiking easy. The spikes are then threshed manually by rubbing or trampling underfoot or by using mechanical threshers of various types. Mechanical threshers are used only by large growers. Small- scale threshers are also becoming popular these days. Fruits are sun dried after threshing. The fruits are then spread out on the floor for drying. Blanching prior to drying improves color and also removes dust and adhering microbial contamination. Drying can be done in sun or in mechanical, electrical and solar dryers for rapid drying. After proper drying the moisture content should be around 8%. Grading of green berries using a mesh is desired to remove the light berries and pinheads and classify based on size. Dried berries are also graded based on size. The dried pepper is cleaned to remove extraneous matter like dirt, grit, stones, stalks, etc., and berries are graded according to their size or density before packing.

10.2 Pepper Processing Equipments

10.2.1 Pepper Thresher

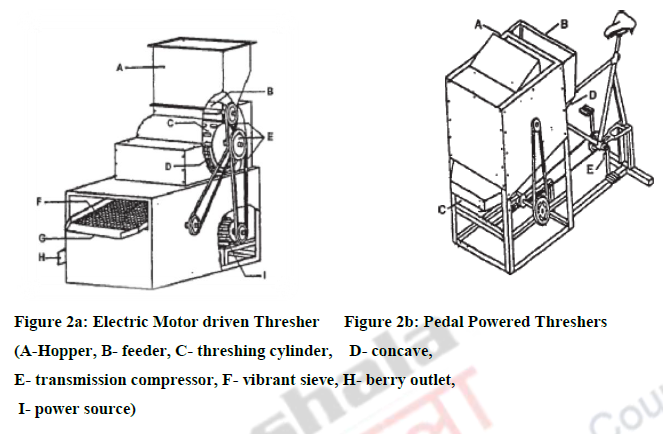

Mainly two types of threshers are used: a) pedal man powered thresher b) electric motor powered thresher. Threshing efficiency of manual thresher is low. The thresher also needs to be equipped with a suitable component to separate berries. This machine is based on the principle of friction and impact mechanism. The pedal powered thresher can be applied at the smallholder farming level, whereas the electric motor powered thresher is more effective at large farming level. This pepper thresher consists of five main parts i.e. threshing part, hopper, separation part, outlet (spikes and cores) and power source (Fig. 2a, b)

10.2.1 Pepper Decorticator

Cylinder, disk and fin type decorticators are commonly used. Cylinder and din types have similarity in mechanism of decorticating, but have limitations due to occurrence of defection on surface of the cores. This weakness has been minimized by using disk type decorticator. The decorticating mechanism of disk type is based on the principle of pressure and friction as well as combination of these principles. The objective of the mechanism is to crush or damage the structure of the skin of berries without damaging the inner core. The pepper decorticator consists of four main parts i.e. decorticating part, hopper, outlet and power source.

10.2.2 White Pepper Processing

White pepper is manufactured by one of the following techniques:

(1) Water steeping and retting technique—either from ripened fresh berries or from dry berries

(2) Steaming or boiling technique

(3) Chemical technique and

(4) Decortication technique.

10.2.3.1 Water steeping technique or retting process

The crop is harvested when one or two fruits in a spike start yellowing, thrushed and heaped in tanks through which water is allowed to run for 7 to 10 days. The light fractions of the pepper like pin heads and light berries which come to the surface are removed and the remaining mass is rolled over at least thrice a day during the retting stage. On the eleventh day the outer skin is removed by gentle rubbing and the deskinned fruits are put in another tank containing bleaching solution. It is then allowed to stay in the bleaching solution for two days after which they are drained, washed and sun dried.

10.2.3.2 Boiling technique

This technique, developed at the Central Food Technology Research Institute (CSIR), Mysore, India involve steaming or boiling the mature green fruits for 10–15 minutes. The outer skin of the fruits gets softened during the steaming process and is removed by passing through a pulping machine. The deskinned fruits (seeds) are washed and treated with sulphur dioxide or bleaching powder solution after which they are washed and dried in the sun. The skin recovered from this process may be used for the recovery of pepper oil by steam distillation though it may not be economical.

10.2.3.3 Decortication process

Of the several processes described, the traditional retting process is the most popular and the product obtained by this process is preferred by the consumers. Whole dried black pepper fruits can be processed to white pepper by employing decorticating machines. The loss of pepper due to breakage will result in reduced yield and hence the white pepper obtained by this method is expensive. Also, the characteristic decortications associated with the traditional product is lacking in the white pepper obtained by 4decortications technique and hence not preferred.

| you can view video on Pepper: Processing of pepper |