16 Enzyme Application

Objectives

- Enzyme and its importance

- Enzyme as an analytical agents

- Applications of enzyme in technology industries

- Enzyme in Biofuel productio

Concept Map

Description

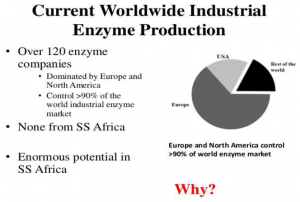

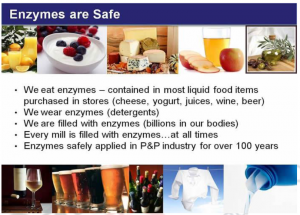

The enzyme technology provided a new route for manufacturing bulk and high added-value products utilizing enzymes , in order to meet needs such as food (e.g., bread, cheese, beer, vinegar), fine chemicals (e.g., amino acids, vitamins), and pharmaceuticals. The enzyme based processes has gain momentum in various sectors such, as in washing and bio-remediation, or for analytical and diagnostic purposes. The two main challenges for enzyme technology are

- the development of new and better products,

- the improvement of processes to produce products from renewable sources.

Novel Applications

- Medical Enzymes

(a) Analytical/ Diagnostic enzymes

(b) Biosensors

(c) Therapeutic Enzymes

- Industrial Applications

(a) Pharmaceutical industry

(b) Food and brewing industry

(c) Paper and pulp industry

(d) Agriculture industry

- Biofuel.

Amylases, cellulases and proteases are most commonly used enzymes, they are used in food, brewing, paper and textile industry.

Applications of enzyme in medicine

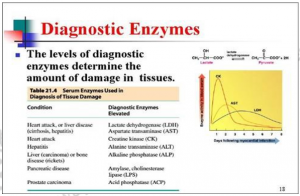

a. Enzymes as Analytical Agents

Enzymes are proven to be eminent analytical reagents due to their highly specific nature and efficiency. They can be used in quantative determination of substrate concentration.

Alcohol dehydrogenase one of the most useful enzymes for bioanalytical applications. There are many other examples of enzymes that can be used in diagnosis.

- Arginase: for L-arginine levels in plasma and urine

- Cholesterol esterase: for serum cholesterol levels

- Creatine kinase: for cardiac and skeletal malfunction

- Glycerol-3-phosphate dehydrogenase: determination of serum triglycerides

- Uricase: for uric acid

Other examples of diagnostic enzymes are shown below

b. Enzymes in Biosensors

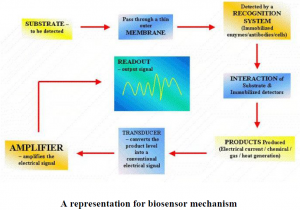

Biosensors are electronic monitoring devices that make use of an enzyme’s specificity and the technique of enzyme immobilisation.

Components of biosensor are

- bio-recognition

- biotransducer

- Amplifier

- processor

- Display

The substrate is detected by bio-recognition system. In this component biomolecule interect with the analyte of interest. The interacting molecule is detected by transducer. The amplifier amplifies the electrical signal produce by transducer. This signal is processed by processor and display on screen.

Advantages:

- highly specific as compared to cell based sensors

- short reaction time or faster responds

Disadvantages:

- they are too expensive to produce as a additional step of isolating the enzyme

- the stability of enzymes get hindered during isolation

- co-factors are required for the detection of substances

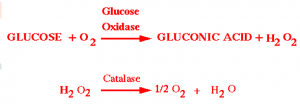

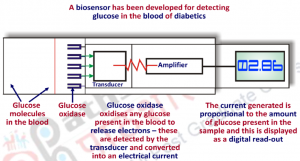

Glucose Biosensor

One of the most widely used biosensor is the glucose biosensor. This biosensor has been proven a boon for glucose sensor research as it can measure the glucose concentration in blood. There are limited enzymes which could be used as glucose detectors as most of the enzymes require cofactors. One of the enzyme which can be used in glucose detectors is glucose oxidase.

According to reaction there are two possibilities to measure the glucose concentration: either one measures the oxygen consumption or the hydrogen-peroxide production. It can also possible to measure the rise in temperature due to energy released in reactions.

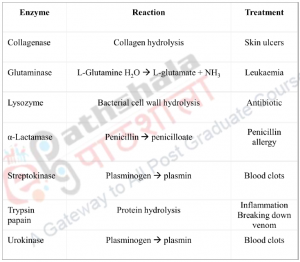

c. Therapeutic enzymes: the given table shows some of the enzymes used in the treatment of various diseases.

Industrial applications

a. Enzymes in Pharmaceuticals Industries:

The enzymes are playing important role in pharmaceutical industries. They can be used as drugs.

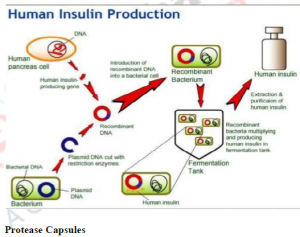

Insulin

This hormone is essential for controlling blood sugar. Diabetes mellitus is a disorder which results due to deficiency of hormone insulin. Since from 1922 this hormone is using in treatment of diabetes mellitus.

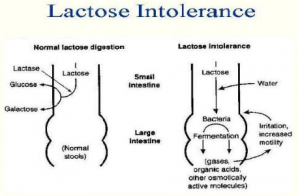

Lactose Intolerant

Lactose intolerant is the inability to digest lactose. So there are supplements for this disorder which are better alternative.

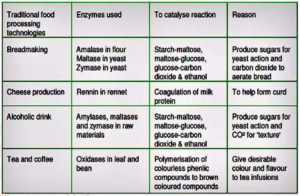

b. Food and brewing industry

One of the important application of enzymes in industries is food processing. Some important enzymes used in food processing are:

Enzymes in Food Products

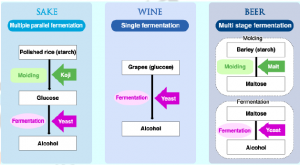

Micro-organisms have been used for thousands of years for making products such as wine, beer, vinegar, soy sauce, bread and cheese. The micro organisms (such as yeast) are really used as a source of enzymes during the manufacture of these products of biotechnology.

For example in bread making, amylase E is used to breakdown flour into soluble sugars, which are transformed by yeast enzymes into Alcohol.

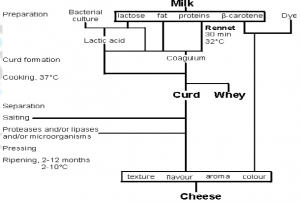

(I) Cheese making

The initial step in the production of cheese is coagulation of milk protein casein. For this, enzyme chymosin or rennin is used which is obtained from calf stomach or microorganism. Chymosin is an aspartic acid protease which causes the coagulation of milk, a process which involves cleavage of a single peptide bond in k-casein. There are other proteolytic enzymes which can be used are trypsin that is also responsible for clotting of milk. One of the disadvantage of degrading casein is that it leads to undesirable flavours. The other enzymes which can be used in food processing is lipases. Lipase is known to modify flavour by synthesizing esters of short chain fatty acids and alcohols, which are known flavour and fragrance compounds. They are also used in dairy industry for the breakdown of milk fat.

(II) Meat tenderizing enzymes

Normal meat is tough and this toughness is due to the presence of collagen, elastin and actomyosin. So there is need to make the meat softer. However, amount of protein is responsible for the favourable flavour in the meat. So for tendrization, marination and flavour proteases are used. The two most often used meat tenderizing enzymes are Papain and Bromelain. These are derived from papaya fruit and the pineapple plant.

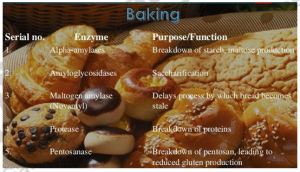

(III) Bakery enzymes

Enzymes in Baby foods

Enzymes also have wide applications in baby food products. The enzymes in baby food have been benefited because they contain pre-digested fat, carbohydrate and proteins. Two majorly used enzymes are lipases and proteases. Lipase and proteases break down fat and proteins respectively.

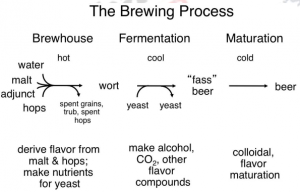

Enzymes in Brewing

Beer and wine are both alcoholic beverages. Both beverages are produced by yeast fermentation of sugars. Wine is manufactured from grapes, and beer from barley. The sugar present in grapes and starch in barley is fermented to alcohol.

Enzymes used in beer and wine making

- Protease at 49-55←C Removes cloudiness formed during beer processing and storage

- β-glucanase (heat-stable) at 60←C :Degrades celluloses, helps saccharification (get sugars), and reduces viscosity

- Amylase (heat-stable) at 65-71←C :Breaks down starch and releases sugars in malt

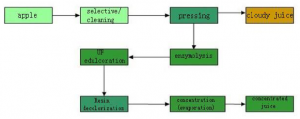

Enzymes have wide application in fruit juice industry. The fresh juice is opaque/ hazy and this problem is mainly due to presence of pectins which are the polymers of α-1,4- anhydrogalacturonic acid. The enzyme used to digest pectins is pectinases. The pectinase helps in releasing more juices, reduce juice cloudiness and stickiness. They are especially necessary for production of clear concentrated juice and help in giving smooth textures, while preserving color and vitamins. Other enzymes which can be used in manufacturing of juice are xylanases and β-glucanases. These enzymes helps further release more juice, reduce juice opaqueness and stickiness. Some amylase are also used if fruits containing starch. Combinations of these enzymes are used to get more juice which are stable and contain good taste.

a) pectinesteras which releases methanol from the pectyl methyl esters.

b) pectin lyase which cleaves the pectin.

c) hemicellulase include xylanases and pectinases

d) polygalacturonase responsible for the random hydrolysis of 1,4-α-D-galactosiduronic linkages;

The optimum pH for enzymatic activity is in between 4 and 5 and the optimum temperature is below 50ºC.

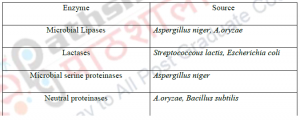

Enzymes used in Dairy products

Dairy enzymes are enzymes used for the manufacturing of cheese and yoghurt and other milk products.

These enzymes are responsible for coagulation that are used in cheese making, to enhance the shelf life and for safety of dairy products.

Microbial enzymes used to accelerate cheese ripening

Enzymes used in dairy can be classified into 5 categories.

1. Coagulants

They used in cheese making by coagulating milk.

Coagulants are class of proteases which is responsible for hydrolyzing the milk protein.

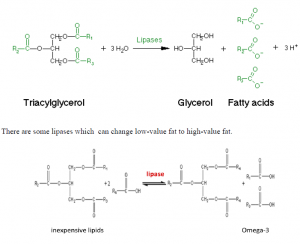

2. Lipase

These enzymes are used to break down lipids and also known to enhanced flavor in aged cheeses.

Crude milk contains lipoprotein lipase which contributes to a tangy flavor in aged cheese by breaking down (hydrolyzing) milk fat to free fatty acids. To overcome this, lipases from external sources may be added during production of cheese to enhance flavor. It may be thought of that lipases which are responsible in generating chain fatty acids contribute to a more desirable, tangy flavor whereas those generate longer chain fatty acids contribute to a soapy flavor.

The lipoprotein lipase present in crude milk is responsible for tangy flavor

3. Yield enhancing enzymes

These are the enzymes which are known enhance the value of dairy products.

There are enzymes which are known for improving cheese yield and enhanced whey value. The yield enhancement may be achieved by increasing fat, protein or moisture retention in the curd.

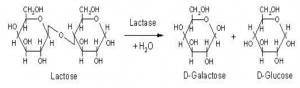

4. Lactase

Lactase are class of enzymes which break down milk sugar lactose. This enzyme is used for producing lactose-free products. Lactose is milk sugar which break down by lactase. This enzyme is important because 70% of global adult population have reduced the lactase production which results in lactose intolerence. This disorder can be treated by using food products containing low level of lactose. Reduced-lactose milk is produced using commercially-available lactase.

5. Bioprotective enzymes

They are responsible for increasing product shelf life by inhibiting microbial growth.

The shelf life of milk is influenced by the microbes present in it. So the most oftenly used method to reduce microbial loads is pasteurisation which results in increasing shelf life. Bioprotective enzymes also offer a natural means to improve food safety and reduce costs associated with microbial contamination, especially in aged products.

Enzymes in edible oil industry

Lipases

Lipases are the enzyme that break down fats (lipids). Lipases perform essential roles in the digestion, transport and processing of dietary lipids (e.g. triglycerides, fats, oils) in most, if not all, living organisms.

Lipases are the important enzymes of lipid industry. They are the biocatalyst which are used to increase the nutritional value of vegetable and animal oils. Lipases upgraded the cheap oils into nutritionally important triacylglycerols.

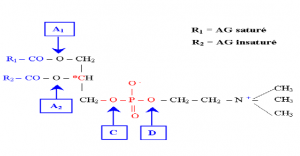

Phospholipase

Phospholipases are incorporated in process such as the degumming of vegetables oils during refinement for removing undesirable compounds and to increase their shelf life. It is also used as mayonaise production from egg yolk.

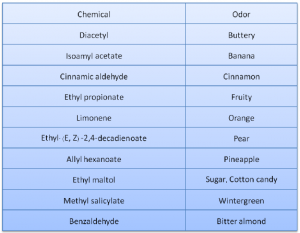

Artificial Flavors

The use of enzymes in flavour synthesis is an important alternative for these synthesizing processes, because the obtained products can be labeled as “natural” and they have better smell and colour than products obtained from chemical esterification. In addition, natural flavouring products can also be obtained by fermentation or bioconversion using microorganisms as Geotrichum, Kluyveromyces, and others.

Lipases have been successfully applied in the production of flavours and fragrances, in non-aqueous media, under appropriate working conditions.

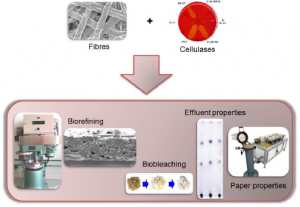

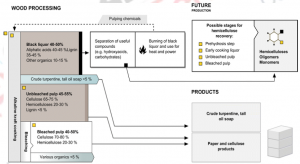

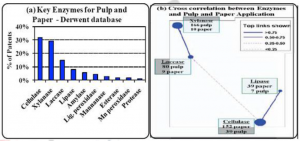

c. Enzymes in Pulp and Paper industry

To meet the needs, to reduce manufacturing cost, to reduce the pollution load, pulp and paper industry are switching onto enzymatic processes. This industry processes large quantities of lignocelluloses biomass every year. A wide range of applications in the pulp and paper industry have now been identified.

Enzyme Use in Pulping

Enzymes used in pulping increases the yield of fiber, lessen energy requirements and provide specific modifications to the fiber. Cellulases, hemicellulases and pectinases have been used in paper and pulp industry.

Enzyme Use in Bleaching

The bleaching is to whiten the pulp by changing or removing colored components.

Enzyme Use in Fiber Recycling

Enzymes are used to facilitate contaminant removal, and increase bond strength in recycled fibers.. Some important enzymes used in fiber recycling are:

- Peroxidases and Laccases.

- Cellulase and xylana

Enzyme Use in Fiber Modifications

Cellulases helps in the digestion of insoluble cellulose which results in formation of more flexible fibers which results in increase in pulp quality.

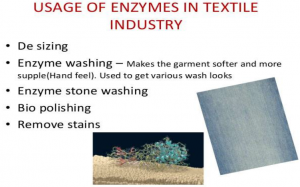

d. Enzymes in textile industry

e. Enzymes in detergent industry:

To remove the oil and other dust entraps in the laundry, the enzymes which are alkaline in nature i.e can work at high pH and at high temperature (themostable) are chosen for the detergent industry. The oily dirt is removed using lipases, the amylases and proteases are also added to the detergents to remove the stains. They are used to remove stains such as blood, grass, sweat and food from clothes. Biological washing powders contain proteases and lipases. Proteases break down proteins and lipases break down fats in the stains into smaller water soluble substances. They still work at the lower temperatures enzymes work at, which makes washing more environmentally friendly.

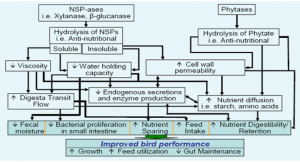

Applications of Enzyme in Agriculture

Enzymes have been used as natural pesticide, herbicide, fertilisers and for odour remover and also added to animal feed to improve digestion of live stock. Enzymes are sprayed in animal farms to reduce infection and to keep insects away. Applying of enzyme to farms proven that the farm is less smelly and is flies free.

Enzymes and Their Use in Animal Feed

Animal feed is the largest cost item in livestock and poultry, accounting for 60-70% of total expenses. The animal feed is supplemented with enzyme additives. The supplement enhances the production of meat per animal.

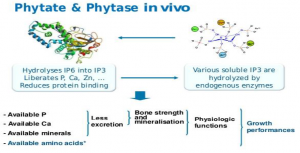

1. Phytases

Phytate is hydrolyse by Phytases. Phytases is a substrate rich in phosphorus, Calcium and other minerals. These nutrient are necessary for bone strength, minerilisation and various other physiological functions such as growth, maintenance and tissue repair.

2. Carbohydrases

Carbohydrases are the common feed enzymes as food assimilation enhances due to better digestion of carbohydrates which increases muscle mass in feed stock. Common Carbohydrase enzyme used in pig diets and substrates

3. Proteases

Proteases hydrolysis the peptide bonds in proteins and convert them to peptides, and amino acids.

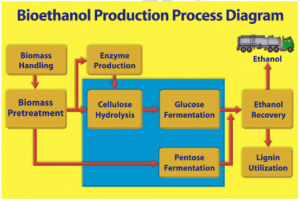

Enzymes help in biofuel production

- Biofuel production provides an alternative to fossil fuels

- Enzymes converts grains into fuel ethanol, plus enzymes that assist the conversion of biomass for cellulosic ethanol.

- A new enzymatic transesterification process has been developed to address prevailing concerns about biodiesel production technology.

- lipases (triglyceride hydrolases) are mainly used for biodiesel production.

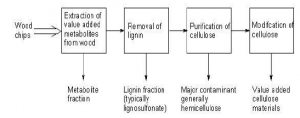

Cellulosic Ethanol Production

The biomass is pretreat to remove non-cellulose biomolecules such as lignin. The pretreated biomass was subjected to enzymatic hydrolysis using cellulases to produce six carbon sugars such as glucose. The microbial fermentation converts sugars into ethanol.

Summary

- Enzymes are polymers of amino acids and are highly specific in nature

- The catalytic activity of the enzyme is dependent upon its three dimensional structure

- They are considered as green catalyst

- Enzymes are biological workhorses; all the vital reactions are catalyzed by them

- Enzymes are used in health sector from analysis to therapeutics

- They are the major players of all industrie Food, wine, leather, detergent etc.

- The food we eat, the cloths we wear, the leather bags we carry, the detergents we use all consists of enzymes

| you can view video on enzyme application |